BACKGROUND

The volumetric controls that currently apply to LAGs were developed and disseminated by ICAO following the unveiling in 2006 of a terrorist plot to sabotage aircraft in-flight by assembling

an improvised explosive device using hazardous ingredients carried in seemingly ordinary LAGs.

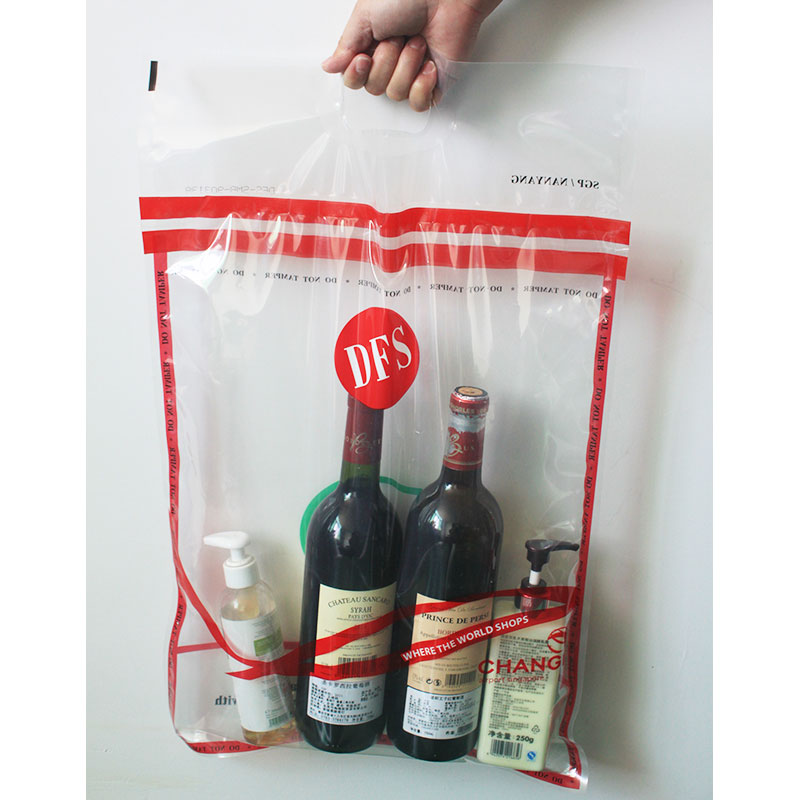

Security tamper-evident bags (STEBs) were developed to allow an exemption to volumetric controls for liquids purchased at airport retailers or on board aircraft and carried by transfer passengers. Details concerning their production, of particular interest to potential suppliers, are available on the linked pages.

DEFINITION OF LAGS

LAGs include (but are not limited to) water and other drinks, soups, syrups, jams, stews, sauces and pastes; foods in sauces or containing a high liquid content; creams, lotions,

cosmetics and oils; perfumes; sprays; gels including hair and shower gels; contents of pressurized containers (e.g. aerosols), including shaving foam, other foam and deodorants; pastes including toothpaste; liquid-solid mixtures;

mascara; lip gloss or lip balm; and any items of similar consistency at room temperature.

SECURITY PRINCIPLES APPLICABLE TO STEBS

General guidelines

LAGs purchased at airport retail outlets or on board aircraft during the day(s) of the journey may be allowed through security screening points provided that they are carried in a

Security Tamper- Evident Bag (STEB).

Production of STEBs

STEBs are to be manufactured in accordance with the technical specifications listed in the next menu <SPECS> as above.

Security procedures should be implemented to ensure that STEBs are not subject to misuse, abuse or any other circumstances that could lead to an act of unlawful interference.

The STEBs should be packed in sealed cartons (or any other suitable form of containers) with adequate measures to show proof upon delivery that the cartons had not been tampered with. The cartons should have adequate inventory records.

Delivery and storage of STEBs

Upon delivery of STEBs to the airport retail premises, the airport retailer or the aircraft operator should implement reasonable security measures to prevent unauthorized

access to or unauthorized removal of the STEBs during storage, delivery to the retailer’s outlets and from their temporary holding premises pending their use at the point of sale.

Movements and deliveries of STEBs are

subject to appropriate authorization and record, facilitating subsequent tracing and auditing, if required.

SUPPLIERS OF LAGS AND/OR STEBS

Suppliers of LAGs and STEBs should be encouraged to provide a declaration of the measures undertaken to ensure the implementation of the security of the supply chain.

Such a declaration should include the following:

Airport retailers, aircraft operators and, where appropriate, suppliers should be responsible for ensuring that the chain of security relevant to supplies of LAGs and/or STEBs is maintained from the first point of entry airside until delivery to passengers.

TSG® STEBs certified with ICAO can be tamper-evident in all circumstances, i.e. for any type of tampering attempts (temperature, solvent, cutting, pre -tampering, etc.), and for any period of time (duration of the journey or longer).

Get Free Samples

Contact Us for Free Samples

TamperSeals (Shenzhen) Limited

Add: No.3336 Songbai Rd, Tianliao Ind. Zone, Gongming Town, Guangming New Dist., 518132 Shenzhen, China.

Tel: +86 755 814 777 50

Fax: +86 755 814 777 90

E-mail: export@tamper-seals.com

*denotes required fields

Material to be used

– transparent (high impact low density polyethylene (LDPE) or equivalent);

– recyclable and environment-friendly products if possible; and

– minimum of 50 microns thickness.

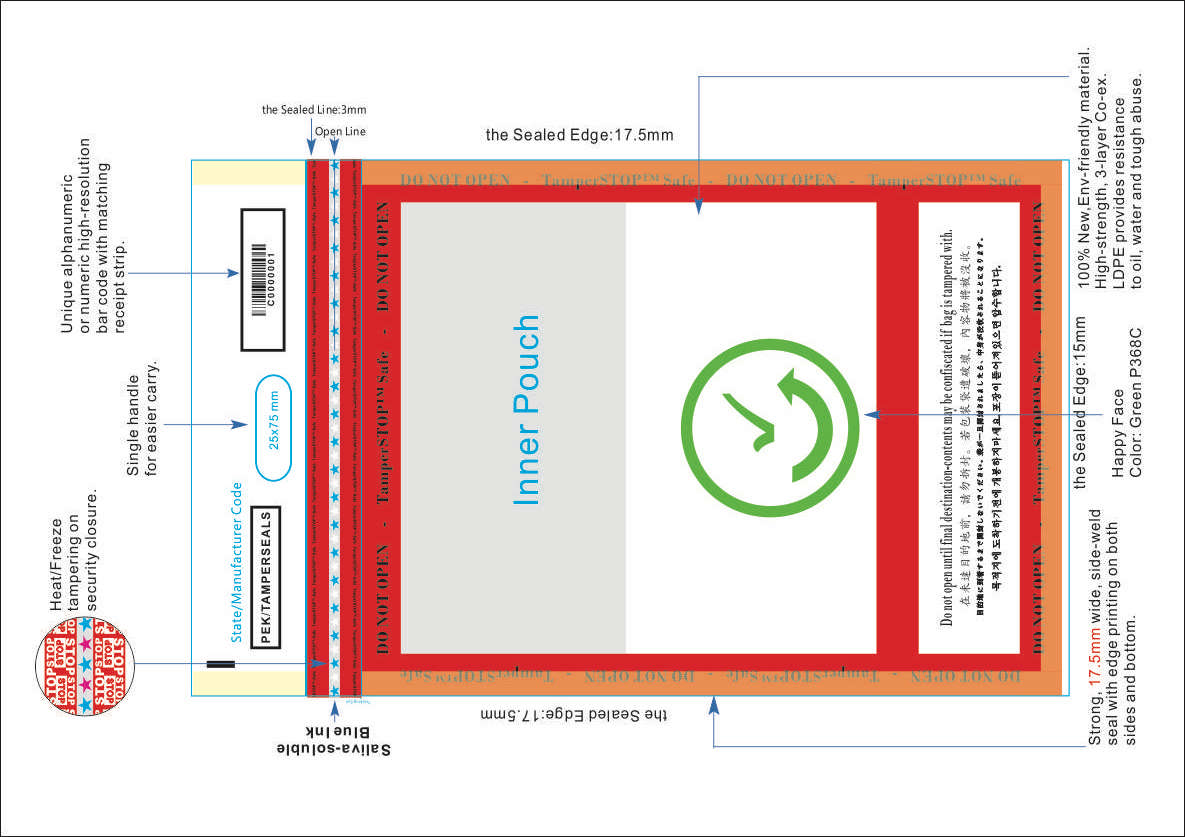

On the top face (front) of the STEB

Closure:

– red tamper evident tape (minimum 30 mm tape with 40 mm release liner); – high tack pressure sensitive self-adhesive; and

– integral security device/hidden graphic to show if tampered with.

Border:

– side and bottom weld be no less than 15 mm width in red; and

– printed border of minimum 5 mm with “DO NOT OPEN”, airport name, or any other continuous message or design which may bleed

over the edge of the bag. (Optional – integral security device/hidden graphic to show if borders are tampered with.)

Message:

– security sign in green happy face in the middle of the security box, and the diameter of happy face should be no less than 1/3 width of bag;

– box in red at bottom stating “Do not

open until final destination – contents may be confiscated if bag is tampered with”.

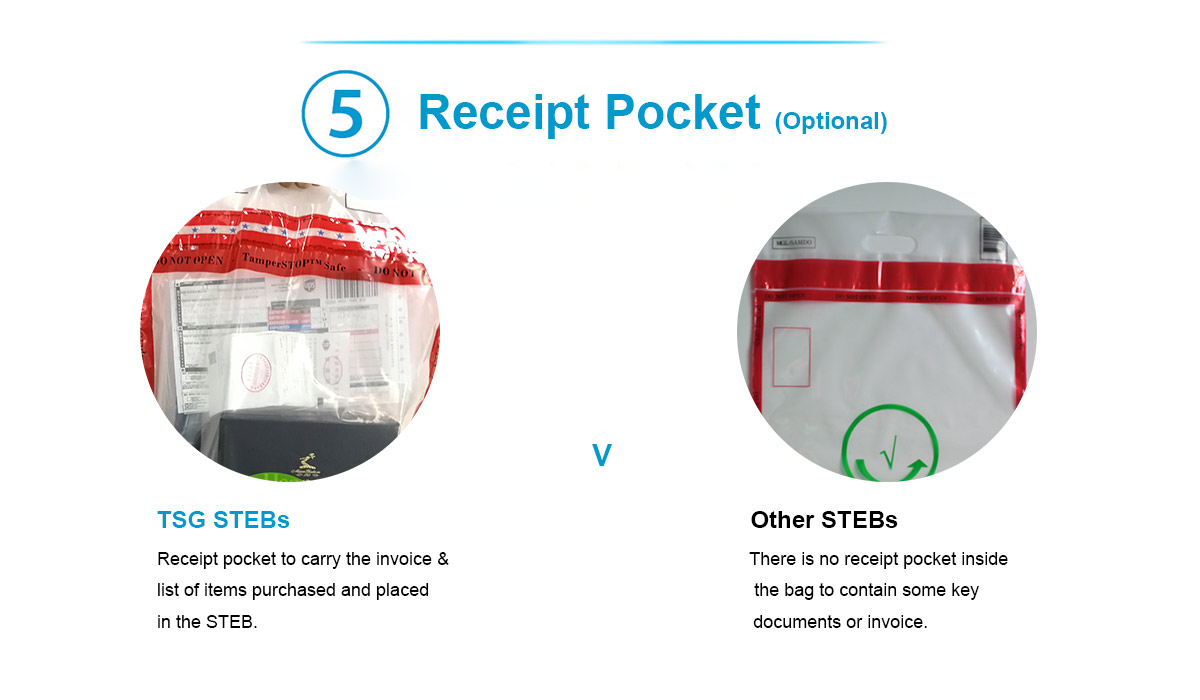

Confirmation/identification features:

– Receipt space (or jacket, optional) inside the bag visible in the top left of the security box. The receipt should contain the following

information:

a) date of purchase (dd/mm/yy or dd/mm/yyyy);

b) place of purchase (State, airport, airline) using international codes;

c) flight number(s) and name of passenger, if possible; and

d) number and list of items

purchased and placed in the STEB.

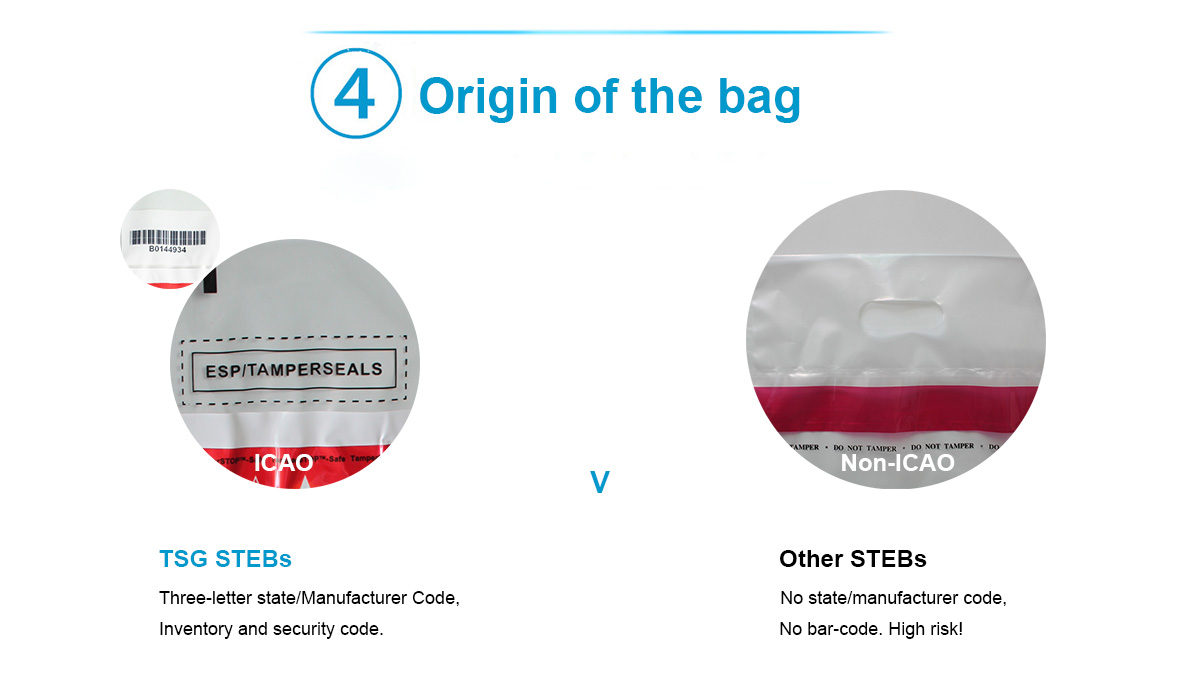

Origin of the bag:

– State three-letter code to determine the State of origin where the STEB was provided to the passenger or airline international code (for duty free sales on board) to determine

the origin of the STEB;

– Manufacturer name (in full pending ICAO’s registration number); and

– Inventory code and security code or device to protect STEB at retailers and shops.

On the back face of the bag:

– Individual airport/retailers/other branding or logos.

You can visit ICAO official website: https://www.icao.int/Security/SFP/LAGS_STEBS/Pages/default.aspx, then click the left menu <List of STEBs Manufacturers> to find us with a capital letter “T”.

Or

Bag Dimensions

The dimensions of a TamperSTOP® security bag will vary according to specific customer requirements.

The external dimensions of a TamperSTOP® security bag are described in mm

as follows: Internal bag width (A) x Internal bag length (B). This is illustrated below.

The useable dimensions are described as follows: External bag width = A + 35 mm sides weld, External bag length = B + 15mm bottom weld + 100mm Handle.

All dimensions may vary within the following tolerances:

|

Bag width (up to 300mm) |

+/-5mm |

|

Bag width (300mm+) |

+/-10mm |

|

Bag length |

+/-10mm |

|

Bag thickness |

+-10% |

Certain dimensions remain constant regardless of the overall dimensions of the bag.

Track & Trace Features and Number Management

A unique number can be printed on each bag. This number can be printed in human eye- readable form and in high definition barcode form.

Barcode

symbology and check digit formula will be agreed with individual customers. Minimum decode rate for barcodes will be grade C according to the CEN/ANSI standard.

The position of number and barcode printing is agreed

with individual customers and is as indicated and approved on bag artwork.

Configurations available include picket and ladder and extra high barcodes (up to 50mm) for first time scanning.

Picket and Ladder barcode configuration

Software systems and stringent procedures are in place at TSG to ensure that the number sequences printed onto TamperSTOP® security bags are as agreed

with customers and in particular that no numbers are duplicated.

All data is electronically collected at point of manufacture. TSG reports on the number ranges printed on bags as follows:

Carton: the label

on each carton indicates the actual number range in that carton along with any numbers missing from that range, upon the client’s particular requirement.

Pallet: the pallet manifest contains a summary of the cartons

on the pallet. It lists the actual number range along with any numbers missing from that range. The manifest is available printed as an A4 sheet, via e-mail or in a format suitable for loading into the customer’s system

electronically.

Print

TamperSTOP® Security bags are printed to specific customer designs. Customer approval of paper artwork proofs and colour samples is required before any manufacturing can proceed. The process

used is flexographic printing.

Packaging

TamperSTOP® security bags are packaged according to specifications agreed with individual customers into polythene bags and cartons and onto pallets as required.

The following information

is printed on the box labels: date of manufacture, TSG order number (manufacturing batch), quantity, and box number. In addition, if bags are uniquely numbered, the start and end numbers of the range of numbers in that

box will be recorded along with a record of any numbers missing from the sequence.

Storage Conditions

The envelopes must be stored in cool dark conditions, in their original packaging until required for use. It is especially important that they are not exposed to sources of ultra

violet radiation, such as strong sunlight or positions close to fluorescent lamps.

Recommended storage conditions are 18 to 22oC and 35-55% relative humidity. The envelopes must not be exposed to temperatures above

35oC for prolonged periods before use.

Shelf Life

Under the conditions specified above, the envelopes will remain suitable for use for a period of 24 months.

Trace-ability

TSG maintains records that allow full traceability of any envelope back through the production processes to its raw material constituents. Quality control records are held for 4 years.

TSG Security & Durable Mailers is ISO 9001:2000 registered.

Intellectual Property Rights & Trademarks

TSG is the market leader in developing tamper-evident packaging solutions for cash and valuables handling. TSG has pioneered tamper-evident security

bags to the current levels of performance. Many of these developments are the intellectual property of TSG. In order that TSG’s intellectual property be clearly communicated and protected all TamperSTOP® security bags carry

the patent information.